obotic combat, a competition in which custom-built machines fight each other, has gained popularity in the last 30 years. The sport has become so popular that competitions are found nearly everywhere from high school gyms to regional, national and global venues. It even inspired a couple of reality TV shows, like “Robot Wars” and “BattleBots,” that document the drama and thrills of these good-natured skirmishes.

One of the sport’s earliest fans is Simon Arthur, the founder of Big Blue Saw, a 6,000-square-foot job shop in his hometown of Atlanta. A software engineer as well as science fiction fan, Arthur was introduced to the “sport” when he attended Dragon Con, an annual science fiction convention. The headliner guest speaker one year was Marc Thorpe, a California-based toy designer credited with inventing the game.

“Thorpe showed us videos from ‘Robot Wars,’ the event he first produced in San Francisco in 1994. Yes, it was a game of destruction and brawn,” says Arthur, “but it also showcased the elegance and beauty of design, and more importantly, it required brains to win. My mind was blown, and I was hooked on making fighting robots.”

The level of robotic engineering and sophistication involved in building these competitive robots does vary from straightforward designs, like radio-controlled vehicles, to more advanced units, with articulating arms and motor-driven saws. The more competitive teams will turn to advanced manufacturing techniques and materials. That is what happened in Arthur’s case.

Arthur tried taking his custom part designs to machine shops and fabricators in his area but learned most shops would not take on small jobs with a limited number of parts, and if they were willing to take the job, then quality became an issue.

After disappointing results and nowhere to turn, Arthur opened his own shop in 2005. He made low-volume parts his core business and focused on competitive pricing and short lead times. He leveraged the internet to reach more customers and offered instant quoting capabilities for a variety of machining and fabrication services.

“Our most popular materials are aluminum, stainless steel and polycarbonate plastic. Typical thicknesses range up to about ½ an inch, but we’ve been known to cut up to 1½-thick material with our waterjet,” explains Arthur. “We also have jobs that use carbon and alloy steels, titanium and other kinds of plastics.”

Recently, Arthur sought to upgrade his shop with a new machine that meets certain specifications, but he was also thinking about ease of use and manufacturer support.

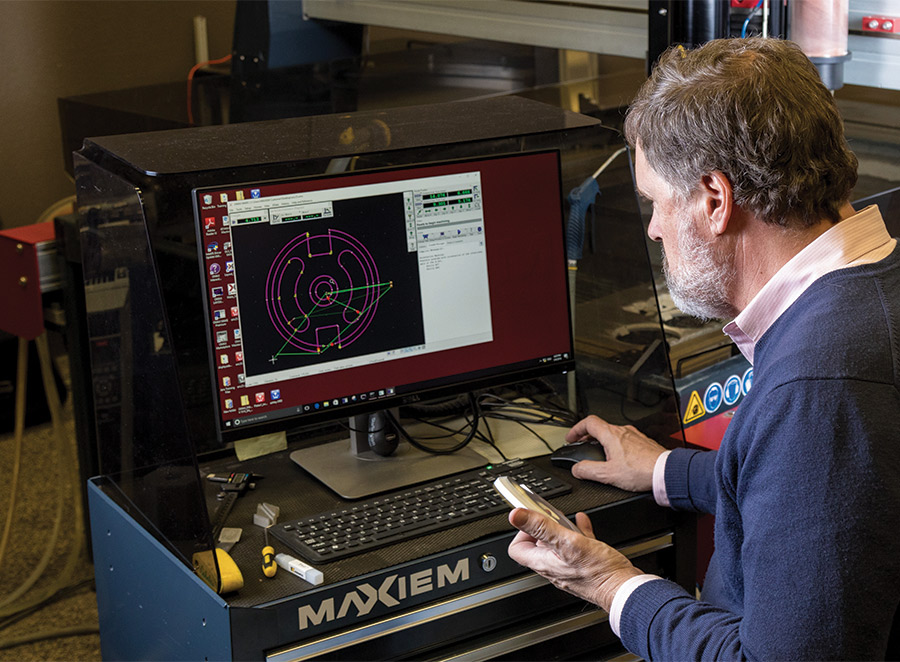

“I looked at several of the large manufacturers but I felt most confident about OMAX. It helped that many of my manufacturing partners and contacts from ‘BattleBots’ already preferred them,” says Arthur. “OMAX machines are reliable, and I found the software is easy to use. Plus, there is a large install base, so I knew it would be easy and convenient, to get replacement parts. It also helped that the distributor was right up the road.”

It’s easy to process materials since the bed can accommodate 4-foot by 8-foot plates, with room left over.

It’s easy to process materials since the bed can accommodate 4-foot by 8-foot plates, with room left over.

“It’s been a pleasure to work with,” says Arthur. “It’s easy to train new operators on. It’s easy to process materials since the bed can accommodate 4-foot by 8-foot plates, with room left over. The software [allows] adjustments to be made on the fly.”

Every OMAX waterjet, including the MAXIEM, comes with the proprietary IntelliMAX software, which can be loaded onto a PC. It works with third-party CAD/CAM platforms and file formats. This is helpful because Arthur’s company receives a variety of design files from customers via their website. Once a design file is imported, the software will automatically create the part pathing files for quoting and set up the machine to ensure the best outcomes.

The flexibility of the software and machine are especially helpful since Arthur is getting even more jobs these days. He recently joined forces with Xometry—a global marketplace that connects customers with manufacturers who make industrial parts on-demand. The acquisition means Arthur is now able to use Xometry to reach millions of more buyers looking for the types of waterjet parts he can cut. And due to the versatility of his OMAX waterjet, Arthur is ready to cut whatever material happens to come in the door.